FARO CMM Inspection Arm – 3D Scanning (Non Contact) – Probe Inspection

FARO CMM Inspection Arm – 3D Scanning (Non Contact) – Probe Inspection

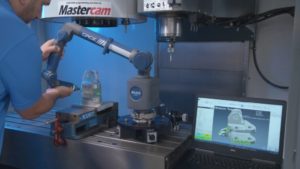

Kettering Precision can use our in house Faro Edge Scan arm for rapid inspection. Using the probe or laser scanning system, the system can gather real dimensional data from the newly manufactured component and compare the size data to the customers digital 3d model. Giving us an instant red or green result.

- Guided Workflows – easily step through the more complex inspection routines.

- Universal CAD Import – direct imports of all major CAD file formats.

- Reporting – generate and share customized, and easy-to-understand inspection reports. (Small charge)

- RPM (Repeat Part Management) – managed repeat inspection within a shorter process time.

The FARO ScanArm is a portable 3D articulated measuring device that resembles the human arm in appearance. The device moves freely with its arm-like joints and is capable of performing measurements either through probing or 3D laser scanning of the target objects. Within seconds, the ScanArm acquires point cloud data consisting of millions of points. Now, scanning with the ScanArm is all it takes to complete your entire inspection process, because the 3D modelling data generated within a few minutes allows technicians to directly arrive at a conclusion. The inspection process, which was previously spread across four or five stages, has now been reduced to a single-stage operation. As a result, the amount of time and labor associated with the inspection is considerably reduced.

The FARO ScanArm is a portable 3D articulated measuring device that resembles the human arm in appearance. The device moves freely with its arm-like joints and is capable of performing measurements either through probing or 3D laser scanning of the target objects. Within seconds, the ScanArm acquires point cloud data consisting of millions of points. Now, scanning with the ScanArm is all it takes to complete your entire inspection process, because the 3D modelling data generated within a few minutes allows technicians to directly arrive at a conclusion. The inspection process, which was previously spread across four or five stages, has now been reduced to a single-stage operation. As a result, the amount of time and labor associated with the inspection is considerably reduced.

Single Point Articulation Performance Test (Max-Min)/2: The probe of the FaroArm is placed within a conical socket, and individual points are measured from multiple approach directions. Each individual point measurement is analyzed as a range of deviations in X, Y, Z. This test is a method for determining articulating measurement machine repeatability.

Single Point Articulation Performance Test (Max-Min)/2: The probe of the FaroArm is placed within a conical socket, and individual points are measured from multiple approach directions. Each individual point measurement is analyzed as a range of deviations in X, Y, Z. This test is a method for determining articulating measurement machine repeatability.

Volumetric Maximum Deviation: Determined by using traceable length artifacts, which are measured at various locations and orientations throughout the working volume of the FaroArm. This test is a method for determining articulating measurement machine accuracy.

CMM Inspection – Laser (non-contact) Inspection – CMM Probe Inspection

Using CAD models to communicate the geometry of a part and applying Geometric Dimensioning and Tolerancing (ASME and ISO standards).

Our measurement procedures can be used on any project, Our customers within ALL industries such as medical, automotive, aerospace, consumer products, tool makers, industrial design and military are benefiting as a result of our CAD-based inspection.

Kettering Precision has the ability to use our in house non-contact 3D laser scanner as well as scanning touch probes to collect data for CAD-to-part comparison. Equipment and reports are traceable to the National Institute of Standards & Technology.